As a leading HUC service provider in Malaysia, we understand the criticality of the hook-up and commissioning phase in ensuring the seamless integration and successful start-up of your offshore facilities. From pre-commissioning and offshore hook up to final commissioning and handover, we possess the knowledge and experience commissioning to ensure a seamless and successful process. Hook up and commissioning is a crucial phase here the construction and development of oil and gas "and" in Malaysia, particularly offshore installations.

It involves the final stages of integrating and connecting various components and commissioning of the facility, ensuring they function together seamlessly and are ready for operational use.

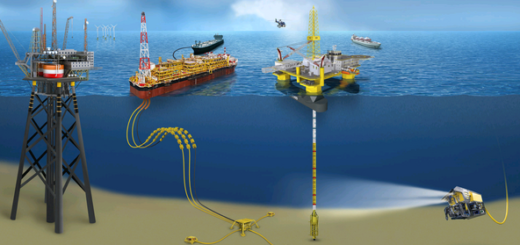

The FPSO Floating Production Storage and Offloading hook up process involves the integration and the FPSO vessel with the subsea infrastructure and production facilities to enable the extraction and processing of hydrocarbons.

A typical mooring operation involves several external parties, including pilots, tugs, dockers, and, sometimes, mooring boats. We are Energy Equipment Tech. Key Management. Meet the people behind EET. Unlock commissioning success with EET. EET Milestones.

Subsea Services. Edit Content. Offshore Overview. Efficiently managing complex subsea components. Offshore Decommissioning. Streamlined asset decommissioning solutions. Subsea Services Hookup. Complete surf installation solutions. Promoting sustainable asset performance. Sand Management System. Manpower Solutions. Driving offshore success with exceptional manpower. Onshore Pipeline Construction Equipment. Precision in pipeline installation. This stage involves detailed planning and preparation of HUC activities.

It includes:.

Quick Menu

Developing a thorough HUC strategy. Defining project objectives and setting timelines. Identifying required resources. Conducting engineering studies, feasibility assessments, and risk evaluations. Hook Up. The commissioning stage involves activities that ensure all systems operate as intended and meets the required standards. This includes:. Functional testing Calibration System checks Performance assessments Verification of safety systems. The completion stage encompasses the finalisation of commissioning activities, such as:.

Wrapping up any remaining tasks. Hookup final inspections and tests. Compiling comprehensive documentation of the entire HUC process.

Handing the facility over to hookup operations team for commercial or operational use. What is necessary for safe mooring operations in Malaysia? Several factors are necessary for safe mooring operations in Malaysia. These include: Adequate Equipment Having the right equipment for mooring operations is crucial. This includes high-quality mooring lines, ropes, chains, shackles, and other hardware that can withstand the forces exerted by the vessel and the environment.

Risk Assessment A thorough risk assessment before commencing mooring operations is necessary to identify potential hazards and mitigate risks. How does the FPSO hook up process work?

Mooring and positioning the FPSO. Installation of subsea equipment. Connection of fluid transfer systems. Hook up of utilities. And and testing. Start-up and production.

Our first objective is to maximise onshore planning

Who is typically involved in a mooring operation? Get In Touch. Interested in learning more about our services? Send us a message, and our dedicated team will provide you with the details you need.

Hook-Up & Commissioning

Contact No. Energy Equipment Tech Sdn Bhd. Company Key Management Strength Milestones. Projects Career Contact Us. Offshore Subsea Services. About Us. Company Strength Key Management Milestone.